LED Backhaul Project Engineer Blog

Measures to prevent loosening of screws

Last Update: April 5th, 2022

Introduction

It has been a few days since the last time I described how screws stop, but this time I will describe how to prevent screws from loosening.

While participating in the formation driving demonstration experiment, we were plagued by loose screws that we had never experienced in any other experimental environment or development environment in an in-vehicle environment subject to constant vibration.

The following is a description of some of the countermeasures that the author has used to deal with such problems.

Threadlocker

This method uses an adhesive that is applied to the threads to harden them. For the purpose of bonding, the oil in the area to be applied must be carefully removed before use.

From the conclusion, in the platooning demonstration experiment, the loosening measures were finally taken by this method. The LED Backhaul also uses a screw lock agent to prevent the screws from loosening.

Threadlockers are available in two types: anaerobic types, which cure by air deprivation when applied to the threads and fastened, and general adhesive-like types, which dry and cure by solvent volatilization.

In any case, since the chemical is in liquid form, it is necessary to be careful of chemical cracks in the plastic parts near the application point. In the past, when we used a certain product during the development of LED backhaul, the resin lens attachment part cracked and shattered miserably. Since then, we have been using a threadlocker that does not damage acrylic resin.

There are also strength categories such as high strength, medium strength, and low strength, with high strength hardening so firmly that it is difficult to disassemble by hand. Therefore, choose according to whether or not the material will disassemble after hardening and the expected fixation strength.

During the demonstration test, the optical system was to be disassembled for adjustment and replacement of the circuit board, and since the parts were only small screws to fix the parts together, not parts that could take the high load of machine operation, a low-strength threadlocking agent was used.

Even in an in-vehicle space subject to constant vibration, we were surprised at the speed at which bolts and nuts loosened, even when torque was controlled during fastening. Since the bolts were loosening intensively at the points where resin and metal parts are tightened together, we assumed that the axial force of the bolts decreased due to the shrinkage of resin parts, especially when they cooled down, because the dimensional change of resin is larger than that of metal as temperature changes. When we determined that countermeasures against loosening were essential, we used a thread-locking agent because the same bolt and nut could be used as usual and because it was easy to remove (as long as it was a low-strength thread-locking agent). The fact that the agent can be applied after fastening to prevent loosening and the fact that it is easy to visually identify the fastened part was also very useful in the experimental environment.

Translated with www.DeepL.com/Translator (free version)

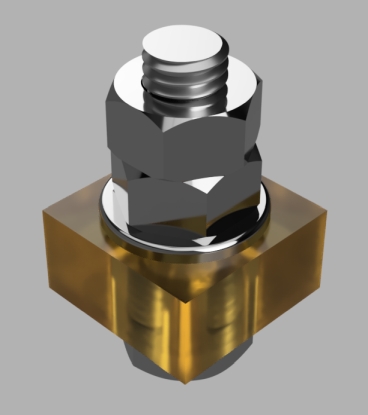

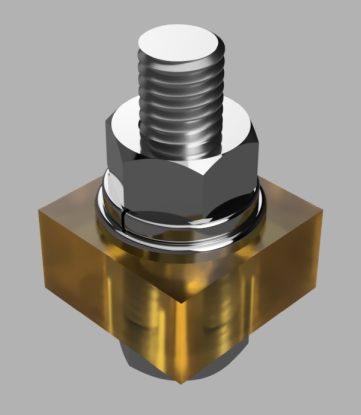

Double nut

Normally, only one nut is used at the fastening point, but a double nut is used when two nuts are used in succession, one on top of the other (lower nut). Double nuts are used on steel towers and anchor bolts.

Although two wrenches are required for fastening, it is a very popular type of fastening because it has a powerful anti-loosening effect and can be easily implemented by simply using two standard nuts.

On the other hand, since two nuts are installed in succession, the shaft length of the bolt and the space required to handle the tools used for fastening are necessary, and if the nuts are not tightened in an appropriate manner, the original effect of the double nut cannot be obtained.

Translated with www.DeepL.com/Translator (free version)

Before adopting the threadlocker in the demonstration test, we used double nuts, but the man-hours required for disassembling and fastening the equipment for adjustment and the craftsmanship required for deep locations were burdensome, and there were many locations where it was not possible to mount double nuts due to space limitations, since they were not intended. We shifted to threadlockers after a few months to improve workability, but the double nuts did not loosen in the areas where they had been used, so we were able to feel the full effect, even though they were small screws.

Translated with www.DeepL.com/Translator (free version)

Spring washer

They are very popular as a loosening stop.

However, there is a paper*1 that suggests it may not be very effective, so the author personally feels uneasy to assume that spring washers alone are sufficient to prevent loosening. (Probably everyone who has considered measures to prevent screws from loosening has seen this.)

Without the spring washer, the frictional force of the thread is lost when the bolt loosens, but with the repulsive force of the spring washer, there is still a small amount of frictional force, so it can be expected to buy time for the bolt to spin out, although this is a very painful phrase to use. We believe that this may be the case. On the other hand, the aforementioned paper suggests that the presence of spring washers may accelerate loosening, so it is difficult to judge.

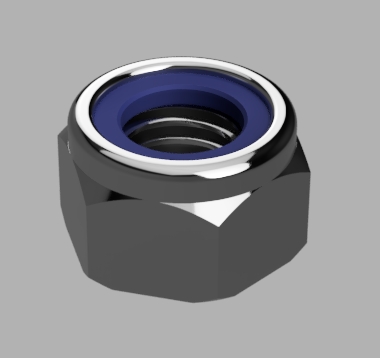

Nylon nut

This nut has a plastic ring on the top of the nut, and the frictional force between the thread and the ring prevents the nut from loosening.

Since the ring is made of resin, it is considered unsuitable for harsh environments due to its reduced effectiveness in high and low temperature environments and inferior chemical resistance. On the other hand, it can be handled in the same way as a normal nut to prevent loosening, and it is less expensive than other nuts with anti-loosening functions, and has been used several times in the author's hobby.

There is also a type of thread locker that forms a thin resin coating on the bolt threads (blue or yellow coating on the threads), but it may be said to be similar to the nylon nut system because it uses the frictional force of the resin to stop the bolt from loosening.

There are also products in which a special metal spring is inserted in place of the plastic ring of the nylon nut, and because the spring is made of metal, it appears to have improved resistance to high and low temperatures and chemicals compared to the nylon nut. (Sorry, we have never used this one...)

Summary

Since the content of this article is based on the author's experience, it has become a memorandum article describing the measures taken in the experimental environment and the reasons why they were taken. Even though it is a prerequisite to apply the appropriate method to the appropriate part to prevent loosening, the easy implementation of threadlockers in existing products and DIY is still a big advantage, so I do not feel that we can get out of the situation where we are dependent on threadlockers.

In addition, I know that there are useful products in the world that have an anti-looseness function, such as hard lock nuts and Nord-Lock washers, but I have limited this blog to areas where I have used them. We would like to make use of such products in our future work.

*1: Masatake KIMURA, Satoshi IZUMI, Shinsuke SAKAI (2007). Self-loosening Behaviour of a Spring Washer :Three-dimensional Finite Element Method Study