LLED Backhaul Project Engineer Blog

Tighten the screws.

Last Update: January 25th, 2022

Introduction

Screws are used to fasten things together, but there have been a number of accidents where truck wheels have fallen off because the screws were not fastened properly.

After the replacement of winter tires and wheels, there was an accident in which it was reported that retightening was not done properly and torque management was not thoroughly followed.

How does a screw stop?

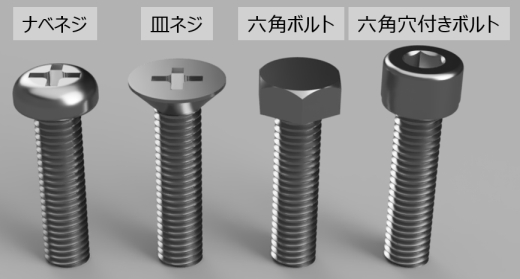

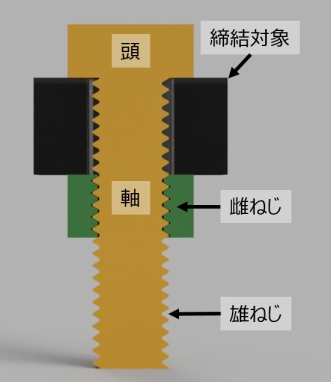

Depending on the shape of the head, there are various types of screws such as nabe-screws, countersunk screws, hexagonal bolts, hexagon socket head screws, etc. All screws are tightened by engaging the threads of the male screw (shaft side) and female screw (receiving side).

Basically, they can be tightened by turning clockwise (CW=ClockWise) with a right-hand thread, and for special applications, they can be tightened by turning counterclockwise (CounterClockWise) with a left-hand thread.

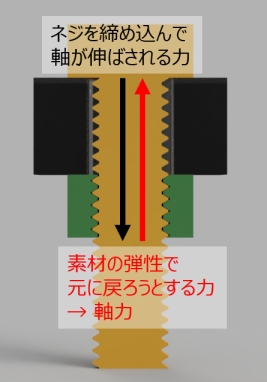

During the process of tightening the screw, it can be tightened with a light force, but as it is tightened further, the head gradually gets caught on the fastening target, and a very large force is required to tighten it further. At this time, the shaft is subjected to the force of the threads meshing with each other to extend and the elasticity of the screw material to return to its original shape, like a spring. This force to return to the original shape = axial force, which stops the screw. It is important to tighten and fix the screw firmly in order to make the axial force work.

Tightening torque

So what happens if we continue to tighten the screw to make the axial force in the previous chapter work properly?

The axial force is generated by the elasticity of the screw material, but if the screw continues to be tightened (stretched), the limit of elasticity will be exceeded and the shaft will not be able to return to its original shape. When the shaft is fully extended, the force to return it to its original shape is not sufficient, so naturally the axial force cannot be obtained.

Axial force is something that needs to be tightened to work, but can be lost if it is over-tightened.

In order to generate the appropriate axial force while preventing elongation, each screw has a set value of tightening torque, although the value varies individually depending on the thickness, material, and application.

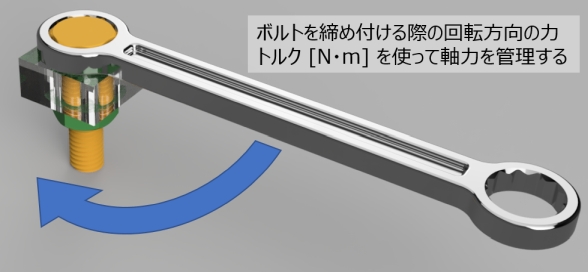

The force to rotate a screw is expressed as torque [N・m], and the axial force on the shaft can be calculated indirectly from the force required to rotate it.

When the screw is first tightened, the torque required for tightening is low, but as it continues to be tightened and the head comes into contact with the fastening object, the torque required for tightening gradually increases. At this point, the torque must be adjusted to the tightening torque set for each screw to complete the tightening process.

It is possible to measure the axial force directly using a measuring instrument, but since the device is large and expensive, it is common to use a tool called a torque wrench or torque screwdriver to tighten it on site.

Thread treatment

As mentioned in the previous section on tightening torque, there is a problem in measuring the axial force from the force to rotate the screw. The problem is the frictional force of the seat surface and screw threads where the head and the object to be fastened come into contact.

Frictional forces can cause loss of torque when tightening, and although it appears that the specified tightening torque has been reached, in reality the intended axial force has not been reached.

The frictional force on the screw threads can be reduced by applying oil or grease to the threads prior to fastening, or by coating the threads with a friction reducing film. Applying oil or grease to the threads prevents direct contact between the metals on the threads, which in turn prevents corrosion from contacting different metals and prevents metals from sticking together under high pressure.

However, there are cases where the fastening is specified to be done in a dry condition without oil/grease application to the threads (in which case, the tightening torque should be specified with the loss due to frictional force incorporated beforehand), so please comply with the manual.

Summary

Screw fastening is based on a variety of factors such as material and torque management. As a worker, I would like to comply with the manual and work safely so as not to damage the intended design.

In this article, we have written about the simple details of the screw stopping mechanism. In the future, we plan to put together an article on stopping screws from loosening, based on what we have learned through product development and field tests.